Tools

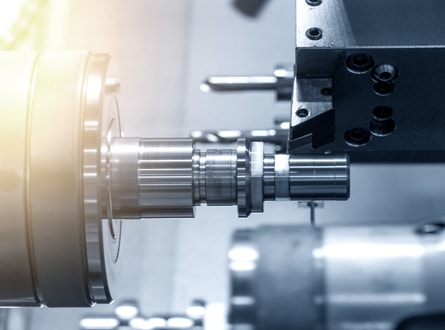

For the professional tool industry, we develop and produce compact cast pieces with considerable functionality. This industry is characterised by the use of steel alloys with high tensile strength, hardness and elasticity. This not only makes these components highly durable, but also capable of withstanding shocks and high mechanical loads.

This processing is often relatively expensive because of the toughness and hardness of the steel alloy. Processing can also be avoided due to the high degree of dimensional accuracy that can be achieved in the process.